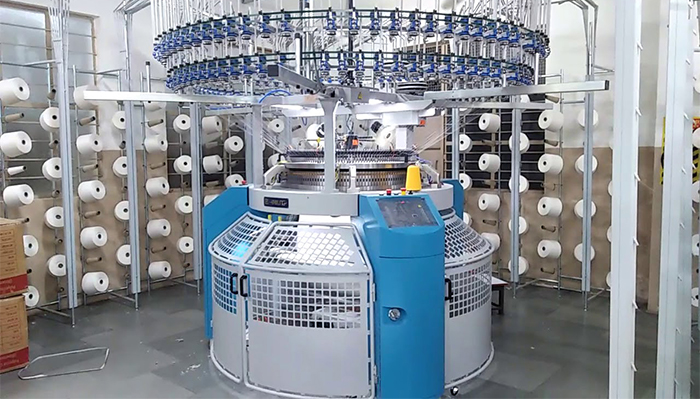

KNITTING

Our sophisticated machinery—which includes a single jersey auto stripper, a rib jacquard auto stripper, and a rib & interlock auto stripper able to produce textiles at a rate of 6000 kg per day.

FABRIC PROCESSING

We use HTHP, MCS, Ferraro, and PLC-controlled Felt Compacting machines for 5-ton daily production capacity, with high-level compacting for high-level production.

PRINTING

Our advanced printing division employs various techniques like discharge, reactive, rotary, fancy, and chest printing, with an Automatic Chest Printing Machine and Semi Automatic Printing Machine for daily production.

EMBROIDERY

Our state-of-the-art, computerised, nine-color Barudan embroidery machine from Japan, which is paired with two instructors, can accurately produce 4000 pieces per day, meeting the demands of modern-day customers.

PRODUCTION

Robust internal production line equipped with top-notch, cutting-edge machinery for production and a 300 CBM storage capacity, as well as the newest equipment provided for product cutting and sewing, and a trained workforce for garment checking and ironing until final stages.

PACKING & WEREHOUSE

With a storage capacity of 20,000 sq.ft. and a corrugation machinery with a dye-cut facility, the facility is equipped with highly competent instructors to operate the machinery for the purpose of packing and warehousing. The output capacity is 3 tonnes of high-quality corrugated boxes per day.

PACKING & WEREHOUSE

The agreement with internationally recognised supply chain and logistics firms helps to ensure that the clients receive the products safely and undamaged.